Recycled plastic spacers for segment stacking

For the storage of prefabricated concrete segments

GREEN SPACERS

From waste to reuse

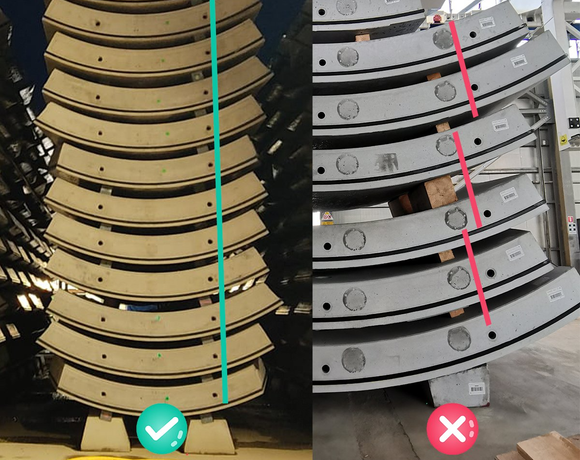

The aim of Green Spacers is to replace wooden spacers, used to stack segments in storage yards (Precast warehouse, TBM site), with recycled-plastic spacers.

MISSION: Green Impact's mission is to develop recycled plastic products that enable circular economy models.

VISION: To contribute to the reduction of environmental impact in the infrastructure prefabrication sector.

Benefits

Improved Safety

- Resistant to attacks by mold and fungi

- Reduced injury risk for workers

- Compliance with robot handling

Project References

WORLDWIDE

Green Spacers have already been adopted in several major infrastructure projects, with over 300,000 units delivered to diverse job sites worldwide.

01

Palermo – Catania High-Speed Rail (Italy)

02

Catania – Messina Railway Line (Italy)

03

Western Harbour Tunnel (Sydney, Australia)

04

Cefalù Tunnel (Italy)

Technical Data

Material: 100% recycled plastic

Weight: < 4kg

Dimensions:

150X H170 X 500 mm

150X H150 X 600 mm

Maximum Working Load:

- 30 tons - size 150X H170 X 500 mm

- 40 tons - size 150X H150 X 600 mm

We also offer project-specific customization, including:

- Varying heights and lengths

- Engraved logos or identification markings

- Tunnel Blocks fibre-reinforced materials

Why are Green Spacers

Eco-friendly?

- Recycled Plastic: use of post-consumer plastic, eliminating the need to produce new plastic

- Second Life of Plastic: Green spacers are produced using plastic that would otherwise be sent to landfill;

- Avoid deforestation:

Green Spacers replace the timber spacers previously used

Do Green Spacers have better performance?

- Better load transmission: precise positioning thanks to the cone guides allow better transmission of forces and increase the stability of the stack;

- Resistance to outdoor conditions:

plastic is less affected by outdoor weathering than wood

Why are Green Spacers Safer?

- Resistant to attack by mold and fungi: avoid the risks of an unhealthy environment for workers

- Reduced injury risk for workers: with its low weight, it significantly reduces exposure of workers to the risk of injury

- Compliance with Robotic Handling:

full management by robot avoids the necessity of workers' presence in storage yards

Our contact

© Green Impact Srl Società Benefit

Via Como 3/5 - Nova Milanese (MB), Italy

PHONE +39 0362827569

Contact us!

Send us your details and we will contact you back to arrange an appointment.

Portfolio

Images from construction sites

A Maccaferri Company

Click & Download our certifications

Quickly access our official, ISO-compliant certifications and our Integrated Policy.